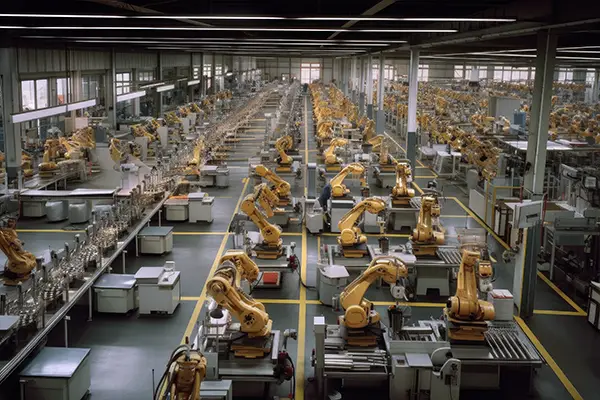

Imagine walking into a pharmaceutical plant or a chemical facility ten years ago. You’d see rows of equipment, engineers with clipboards, and processes that relied heavily on manual checks and batch production. Fast forward to today, and the scene is dramatically different. Digital tools and Artificial Intelligence are rapidly transforming how these industries approach commissioning, decommissioning, and production line changes. This is the story of that transformation—a story of innovation, agility, and the power of digital solutions.

The Challenge: Time, Cost, and Complexity

In many vertical lines of business, such as the pharma and chemical industries, commissioning a new production line or decommissioning an old one has always been a high-stakes endeavor. It’s a process fraught with complexity: thousands of instruments to calibrate, safety systems to validate, and regulatory standards to meet. And when production needs to shift—say, to manufacture a new drug or a specialty chemical—the process of reconfiguring a production line can take months, costing millions in downtime and lost revenue.

But what if there was a better way? What if digital tools could streamline these processes, making them faster, cheaper, and more reliable? That’s exactly what Bravura AI is making happen today.

The Hero: Digital Commissioning

Enter digital commissioning—a game-changer for both continuous manufacturing industries. Instead of relying on manual processes and paper-based documentation, engineers now use digital platforms like Bravura AI and Plant Unity to automate and optimize the commissioning process.

- The Pharma Story: Picture a pharmaceutical company launching a new vaccine. With digital tools used pre-commissioning, they can go on to create a digital twin of the production line, simulating every step of the process before a single piece of equipment is installed. This reduces the risk of errors and ensures compliance with strict regulatory standards. Once the line is up and running, real-time data from IoT sensors allows for continuous monitoring and optimization.

- The Chemical Story: In a chemical plant, digital tools in the planning of commissioning are used to validate safety systems and ensure seamless integration of new equipment. By automating the process, engineers can cut commissioning preparation time in half, saving both time and money.

The Twist: Agile Production Line Changes

One of the most exciting developments is the ability to quickly reconfigure production lines. In the past, changing a line to produce a new product could take weeks or even months. Today, digital tools like Bravura AI’s Plant Unity make it possible to do this in a fraction of the time.

- Pharma Example: A pharmaceutical company needs to switch from producing one drug to another. Using a digital platform, they can simulate the new process, identify potential bottlenecks, and reconfigure the line—all before making any physical changes. This agility is crucial in an industry where speed to market can mean the difference between life and death.

- Chemical Example: A chemical plant needs to produce a new specialty chemical for a customer. With modular, digitally-enabled equipment, they can quickly adapt their production line, ensuring they meet the customer’s tight deadline.

The Bittersweet Moment: Decommissioning

Decommissioning a production line is often seen as the end of an era. But with digital tools, it doesn’t have to be a painful process. Digital decommissioning allows engineers to systematically document every step, ensuring that equipment is safely removed and that valuable data is preserved for future use.

- Pharma: When a drug reaches the end of its lifecycle, digital decommissioning ensures that the production line is shut down in compliance with regulatory requirements. The data collected during the line’s operation can be used to improve future processes.

- Chemical: In a chemical plant, digital decommissioning helps identify opportunities to repurpose equipment or recycle materials, contributing to sustainability goals.

The Resolution: A New Era of Efficiency

The impact of digital tools on commissioning, decommissioning, and agile production line changes is profound. Companies are saving time, reducing costs, and improving safety. But perhaps the most exciting part is the potential for innovation. With digital tools, engineers can experiment with new processes, test new ideas, and push the boundaries of what’s possible.

The Takeaway

This is more than just a story about technology—it’s a story about people. It’s about the engineers who are embracing these tools to solve complex problems. It’s about the companies that are investing in innovation to stay competitive. And it’s about the patients and customers who benefit from faster, safer, and more efficient production processes.

What’s Next?

The digital revolution in pharma and chemical industries is just beginning. As technologies like AI, IoT, and digital twins continue to evolve, the possibilities are endless. The question is: how will your organization embrace these changes?

Let’s discuss! How could you work with Bravura AI to transform your processes? What challenges are you facing?